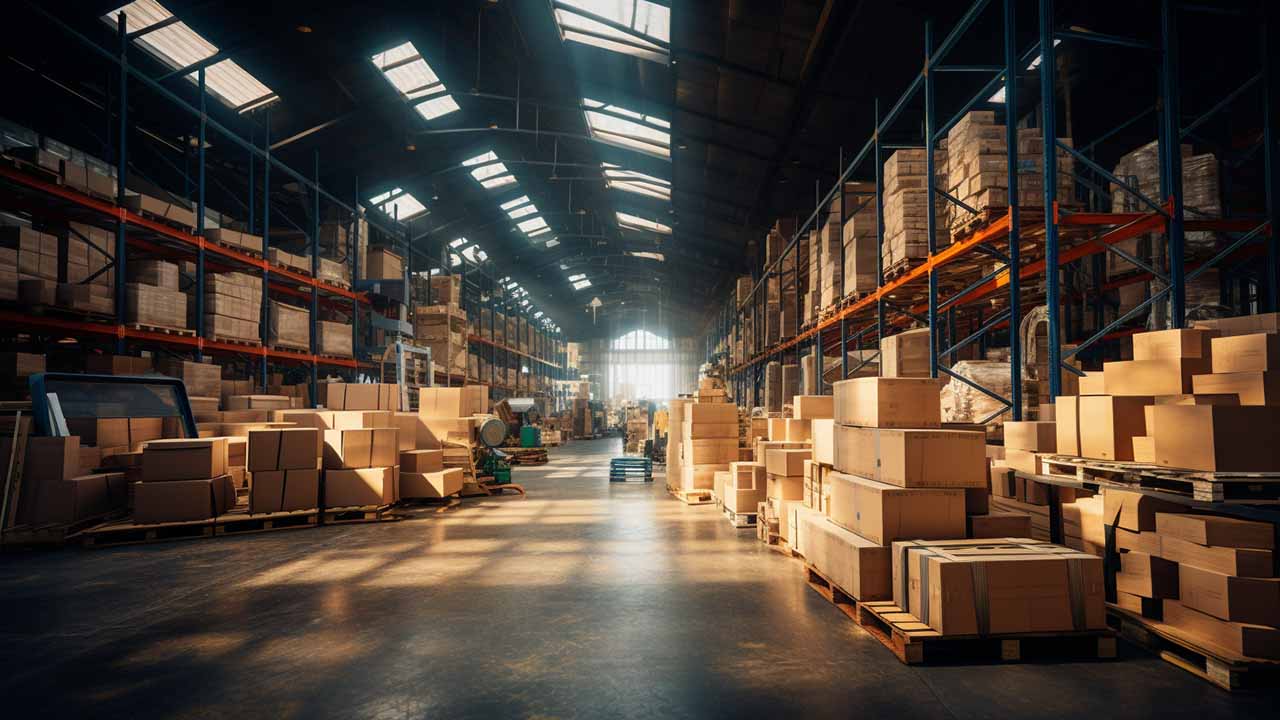

How to customize warehousing solutions based on your inventory?

Customized warehousing solutions are even more critical when inventory volumes, types of goods, and turnover rates vary. Each inventory type requires a distinct handling solution, and selecting the right warehousing solution can enhance operational efficiency, lower costs, and facilitate business expansion.

Evaluate Storage Requirements and Inventory Turnover

Not all inventory sits in the warehouse for the same duration. Fast-moving SKUs require immediate accessibility, while slow-moving or seasonal items can be stored in less accessible areas. This contrast influences warehouse zoning, picking strategies, and replenishment frequencies. Use historical data to categorise your inventory based on movement speed and frequency.

Next, match your inventory turnover with a fitting warehousing layout. High-turnover items are best suited for a pick-and-pack zone, located near the outbound docks. Slow movers, on the other hand, should be placed on upper racks or in distant locations. You can customise warehousing solutions by prioritising space allocation based on movement metrics. Ultimately, matching storage methods to turnover improves speed and reduces unnecessary labour.

Integrate Automation and Smart Technologies

To customise a warehousing solution efficiently, many businesses now turn to automation. Automated Storage and Retrieval Systems (ASRS), conveyor belts, and barcode scanning can streamline operations and reduce error rates. Integrating smart sensors and Internet of Things (IoT) devices allows real-time tracking and environmental monitoring.

Beyond hardware, software solutions like Warehouse Management Systems (WMS) help monitor inventory status, guide staff, and forecast demand. These systems enable data-driven customisation. By analysing patterns and KPIs, you can dynamically adjust slotting, staffing, and storage configurations. Technology-driven customisation boosts responsiveness and minimises waste.

Optimize Layout and Space Utilization

Every square foot in your warehouse matters. Poorly designed layouts lead to inefficiencies, lost time, and safety risks. When you customise warehousing solutions, spatial planning should align with your inventory type and flow. Start by mapping high-frequency routes and placing high-demand SKUs accordingly.

Use vertical space with multi-level shelving, mezzanines, or stacking systems. Implement modular shelving for adjustable flexibility. By optimising space, you not only reduce fixed costs but also increase inventory visibility. Keep in mind that a logical layout reduces travel time and enhances worker productivity. Space optimisation is one of the most cost-effective customisations available.

Align Workforce Strategy with Inventory Demands

People play a vital role in warehouse efficiency. As you customise warehousing solutions, factor in the human element. Determine the number of workers required during peak and off-peak times. Cross-training staff enables flexibility across receiving, picking, and packing.

Additionally, labour management software can forecast workloads and assign resources accordingly. For inventory that requires special handling (e.g., hazardous or fragile goods), consider assigning trained personnel and safety protocols. Aligning your workforce with your inventory profile ensures smoother operations and fewer disruptions.

Build Scalability and Flexibility Into Your Design

Inventory profiles change as businesses grow. A solution that fits today may become a bottleneck tomorrow. Hence, always customise warehousing solutions with scalability in mind—Utilise modular equipment and adjustable racking that can adapt to your evolving needs.

Plan for volume surges, such as those that occur during holiday seasons or the launch of new products. Temporary storage areas or on-demand warehousing partnerships can provide buffer space. Also, consider multi-client facilities if shared storage is viable. Scalability ensures that your warehouse can adapt to shifting business dynamics without costly overhauls.

Leverage Data and KPIs for Continuous Improvement

Customisation isn’t a one-time task. To keep your warehousing logistics solution relevant, continuously evaluate performance. Set KPIs such as order accuracy, picking time, and inventory turnover. Analyse these metrics regularly to identify gaps and inefficiencies.

Utilise these insights to recalibrate storage zones, refine handling protocols, or implement new technologies. Continuous improvement based on real-time data ensures that your warehouse evolves in tandem with your inventory. A data-backed approach helps fine-tune customisation and boosts overall supply chain resilience.

Why You Must Customise Warehousing Solutions to Inventory

By aligning warehousing strategies with inventory profiles, companies can unlock greater value across the supply chain. From innovative layouts to workforce planning and automation, customisation ensures your storage ecosystem stays responsive and efficient.